The powerful combination of artificial intelligence and cutting-edge vision AI systems presents a breakthrough way to reach sustainable steel manufacture without compromising output.

Learn how AI-driven preventive maintenance minimizes equipment downtime in heavy manufacturing. Boost efficiency using computer vision and AI technologies.

Computer Vision AI is changing Asset Performance Management (APM) by enabling real-time monitoring and inspection of industrial assets. Vision AI technology can analyze images and video feeds by deploying advanced cameras and algorithms to identify wear and tear, misalignment, and surface defects.

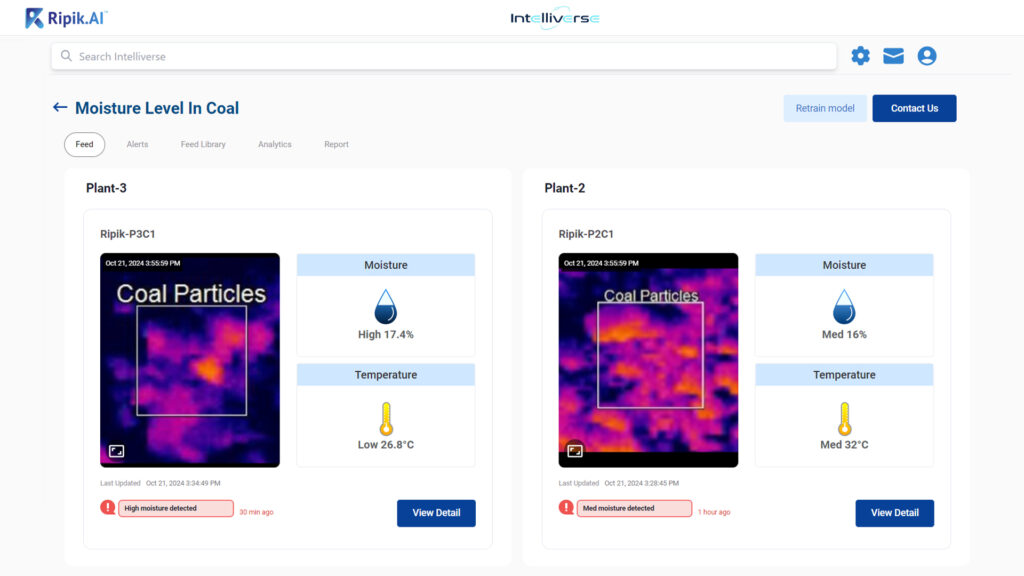

Coal moisture detection ensures that coal is at the right moisture level for optimal burning to enable combustion efficiency.

Enhance Electric Arc Furnace efficiency with real-time monitoring and advanced visual analytics. Track temperature, charge composition, and energy use to boost performance and reduce costs.

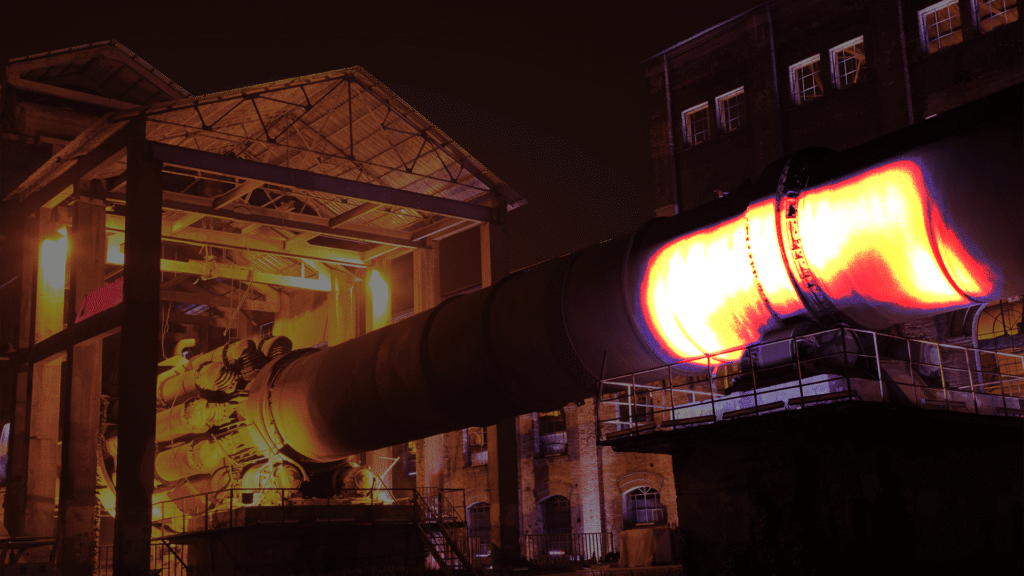

The integration of Vision AI into cement kiln operations presents a transformative opportunity for manufacturers to enhance efficiency, reduce costs, and improve product quality.

Real-time, automated refractory monitoring is a game-changer for high-temperature industries, providing a reliable measurement solution that enhances plant safety and efficiency.

Computer vision is revolutionizing machine monitoring system as it is crucial for optimal performance and preventing equipment failures.

With the boom of AI in the manufacturing sectors, predictive maintenance with AI has arrived as a game-changing approach that is revolutionizing the manufacturing Industry.

Computer vision AI platforms are instrumental in these advancements, offering precise 24/7 monitoring, real-time alerts, and management of production processes.