Accurate raw material moisture analysis plays a pivotal role in industrial operations, directly influencing product quality, energy efficiency, and operational costs. Vision AI and infrared-based monitoring enable real-time monitoring of moisture content in materials with unparalleled precision.

Eliminating downtime in cement plants is no longer a distant goal but a tangible reality with the adoption of AI. Through advanced capabilities like real-time monitoring, predictive maintenance system, and process optimization, AI empowers cement manufacturers to address equipment issues proactively, ensuring uninterrupted operations.

Optimizing cloud architectures for cost-effectiveness is the major goal of such an architecture. The idea is similar to how a city’s structure can be optimized to minimize resource consumption and traffic congestion.

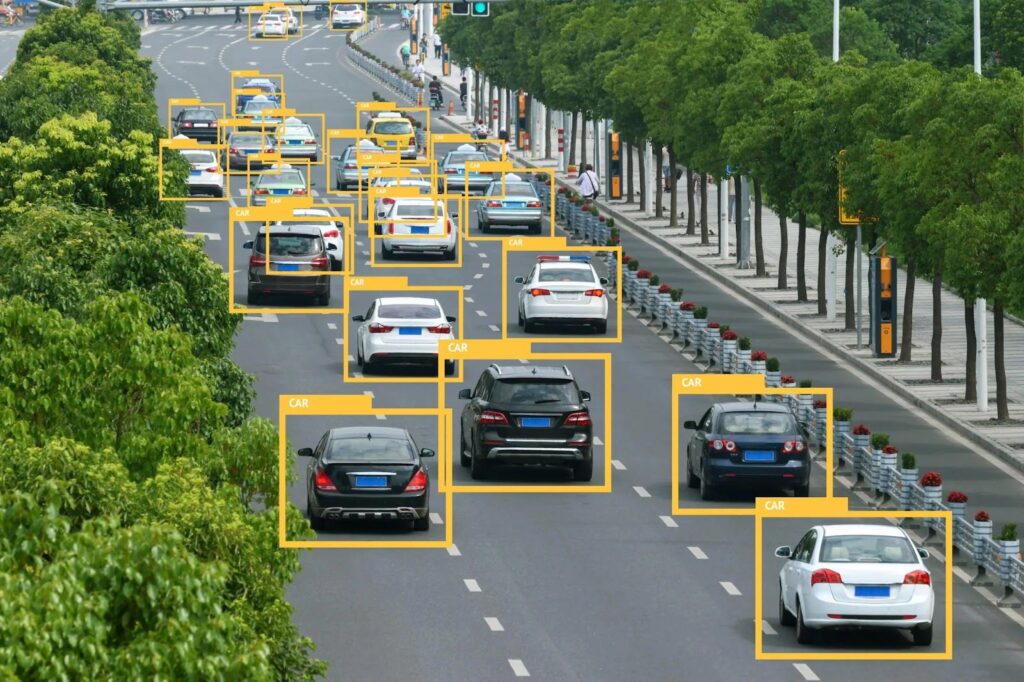

Computer vision technology is a replica of human vision by enabling machines to “see” and analyze images and videos but at a much higher speed and accuracy.

AI is nowadays playing a pivotal role in contributing towards the reduction of the carbon footprint in cement industry. AI for alternative fuel resources enable real-time tracking of alternative fuel quality and distribution, optimizing how fuels like biomass, plastic waste, and refuse-derived fuel (RDF) are fed into cement kilns.

Incorporating computer vision into factory operations will unlock several new opportunities for efficiency, quality, and safety. This is crucial since, on average, over the next three years, the technology is predicted to lead to a CAGR of 9.52% 42% boost in productivity.

Alternative fuels, such as Refuse-Derived Fuel (RDF), a type of solid waste, are increasingly being considered a viable solution. They serve as an alternative fuel option and an efficient method for disposing of municipal solid waste.

Discover how Vision AI, a cutting-edge technology, surpasses traditional ML models to optimize manufacturing processes, enhance quality control, and boost overall efficiency.

Integrating AI in the cement industry is a much-needed breath of fresh air. We’re on the brink of a new era that’s driven by intelligence and innovation. AI has the potential to solve many persistent problems while simultaneously increasing cement manufacturing efficiency.

Research by Nature claims that artificial intelligence can contribute to fulfilling 79% of the target for sustainable development.