Resources

Ripik.ai has been associated with IMFA since Jan 2023 towards implementation of Industry 4.0 in our Choudwar plant located in Odisha. They are working on two machine learning / data science use related to power and metallurgical coke consumption optimization through real-time alerts. The team has good knowledge in the areas of data science & machine learning, and their problem solving skill set is high

I have known Pinak, Arunabh and Navneet since 2017. They were part of Advanced analytics program in TSK between 2017 and 2020 and placed a crucial role in its delivery. The team worked end to end in conceptualization and delivery of the use cases across Blast Furnace, Sinter Plant and Steel Melt Shop.

Ripik.ai has been the analytics partner of Godrej & Boyce since March 2022. They have been doing projects with the Interio and Aerospace businesses already and we are exploring use cases for other businesses as well. Pinak and his team have worked with us closely on these manufacturing use cases. They have an unparalleled understanding of the process and can bring impact very quickly

I am delighted to write this testimonial about Ripik.ai, one of ESL’s analytics partner since January 2023. The Ripik.ai team is working on three use cases in our Upstream section at the Bokaro plant – Digital Twin of Blast Furnace, Burden Mix optimization in Blast Furnace and Green Mix optimization in Sinter Plant Burden Mix optimization in Blast Furnace and Green Mix …

EXPLORE

About Us

Meet our elite squad - some of the brightest minds from Google, MIT, and IITs, pioneering the future at Ripik.AI.

Choose Ripik.AI for innovative Computer Vision AI Solution that drive operational excellence in manufacturing industries.

Join Ripik.AI where learning is more impactful, diversity inspires, and work-life harmony thrives.

Explore the latest breakthroughs, partnerships, and global recognitions shaping Ripik.AI's impact on industrial AI

Discover Ripik AI's latest event appearances showcasing cutting-edge AI solutions for manufacturing.

Industries

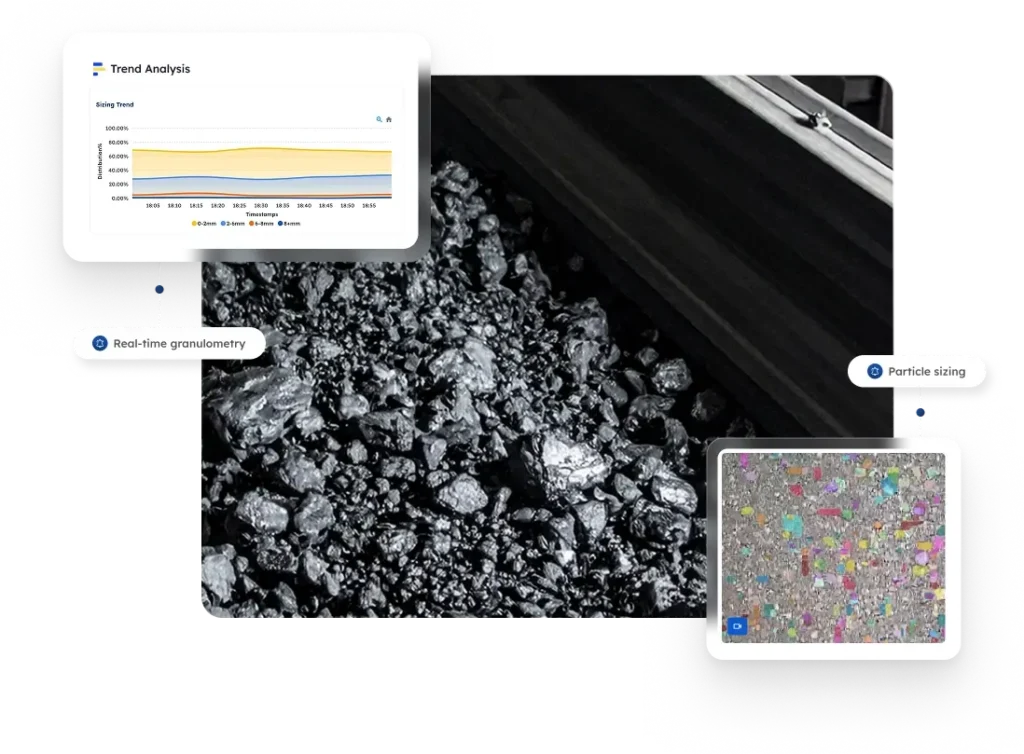

Tackle raw material variability and environmental challenges with accurate, real-time visibility.

Transforming Cement Manufacturing Operations with Our Patented Vision AI SaaS Platform for Process Optimization

Empower operators to precisely control bath temperature and significantly reduce power usage and AIF3 consumption.

Solve high impact use cases and maximize quality by identifying important parameters and sweet spot of operations.

Revolutionizing boiler operations with patented Computer Vision for higher productivity and lower energy costs.

Unlock efficiency and optimize processes across industries with our advanced, and intelligent AI technologies.

Products

Explore Vision AI Agents

Ripik’s Vision AI Agents are your automated pair of eyes — developing intelligent monitoring agents for engineered industrial performance.

Explore Ripik Vision Platform

Move beyond number crunching and reduce process variability with an automated pair of eyes—our Vision AI platform

Curious how Vision AI fits into your operations?

Let us walk you through a tailored demo experience.

Industries

Tackle raw material variability and environmental challenges with accurate, real-time visibility.

Transforming Cement Manufacturing Operations with Our Patented Vision AI SaaS Platform for Process Optimization

Empower operators to precisely control bath temperature and significantly reduce power usage and AIF3 consumption.

Solve high impact use cases and maximize quality by identifying important parameters and sweet spot of operations.

Revolutionizing boiler operations with patented Computer Vision for higher productivity and lower energy costs.

Unlock efficiency and optimize processes across industries with our advanced, and intelligent AI technologies.

Resources

Ripik.ai has been associated with IMFA since Jan 2023 towards implementation of Industry 4.0 in our Choudwar plant located in Odisha. They are working on two machine learning / data science use related to power and metallurgical coke consumption optimization through real-time alerts. The team has good knowledge in the areas of data science & machine learning, and their problem solving skill set is high

I have known Pinak, Arunabh and Navneet since 2017. They were part of Advanced analytics program in TSK between 2017 and 2020 and placed a crucial role in its delivery. The team worked end to end in conceptualization and delivery of the use cases across Blast Furnace, Sinter Plant and Steel Melt Shop.

Ripik.ai has been the analytics partner of Godrej & Boyce since March 2022. They have been doing projects with the Interio and Aerospace businesses already and we are exploring use cases for other businesses as well. Pinak and his team have worked with us closely on these manufacturing use cases. They have an unparalleled understanding of the process and can bring impact very quickly

I am delighted to write this testimonial about Ripik.ai, one of ESL’s analytics partner since January 2023. The Ripik.ai team is working on three use cases in our Upstream section at the Bokaro plant – Digital Twin of Blast Furnace, Burden Mix optimization in Blast Furnace and Green Mix optimization in Sinter Plant Burden Mix optimization in Blast Furnace and Green Mix …

EXPLORE

About Us

Meet our elite squad - some of the brightest minds from Google, MIT, and IITs, pioneering the future at Ripik.AI.

Choose Ripik.AI for innovative Computer Vision AI Solution that drive operational excellence in manufacturing industries.

Join Ripik.AI where learning is more impactful, diversity inspires, and work-life harmony thrives.

Explore the latest breakthroughs, partnerships, and global recognitions shaping Ripik.AI's impact on industrial AI

Discover Ripik AI's latest event appearances showcasing cutting-edge AI solutions for manufacturing.

Products

Explore Vision AI Agents

Ripik’s Vision AI Agents are your automated pair of eyes — developing intelligent monitoring agents for engineered industrial performance.

Explore Ripik Vision Platform

Move beyond number crunching and reduce process variability with an automated pair of eyes—our Vision AI platform

Curious how Vision AI fits into your operations?

Let us walk you through a tailored demo experience.